Scientists propose using pollen to make paper and sponges

At first glance, the Nam-Joon Cho laboratory at the Nanyang technological university in Singapore looks like your typical research installation-scientists who cut, crowded establishments, a buzzing of machines in the background. But orange yellow spots on laboratory blouses suspended on hooks refer to a less usual subject under study.

Powdered coloring is pollen: microscopic grains containing male reproductive cells that trees, weeds and herbs are released seasonally. But Cho does not study the unpleasant effects like hay fever, nor what pollen means for plants that do it. Instead, the materials scientist spent a decade on pioneer and refining techniques to reshape the rigid outer shell of pollen – in polymer so hard that it is sometimes called “the diamond of the plant world” – transforming the grains into a consistency similar to a jam.

This microgel, according to Cho, could be a versatile construction element for many environmental materials, including paper, film and sponges.

Many people think of pollen, when he does not fertilize plants or nourish insects, like useless dust, but he has precious applications if you know how to work with it, Said Cho, who co-authors an overview of the potential pollen applications in 2024 Annual review of chemical and biomolecular engineering. He is not the only scientist to think so. Noemi CSABA, a researcher in nanotechnology and the delivery of drugs at the University of Santiago de Compostela in Spain, wants to develop pollen shells dug in protective vehicles to deliver medicines to the eyes, lungs and stomach.

Researchers who study the usefulness of pollen for people are a rare breed, explains CSABA. “I find it a little surprising,” she said. “Pollen is a very, very interesting biomaterial.”

In relation: The new wonderful material designed by AI is as light as foam but as strong as steel

Soften the shell

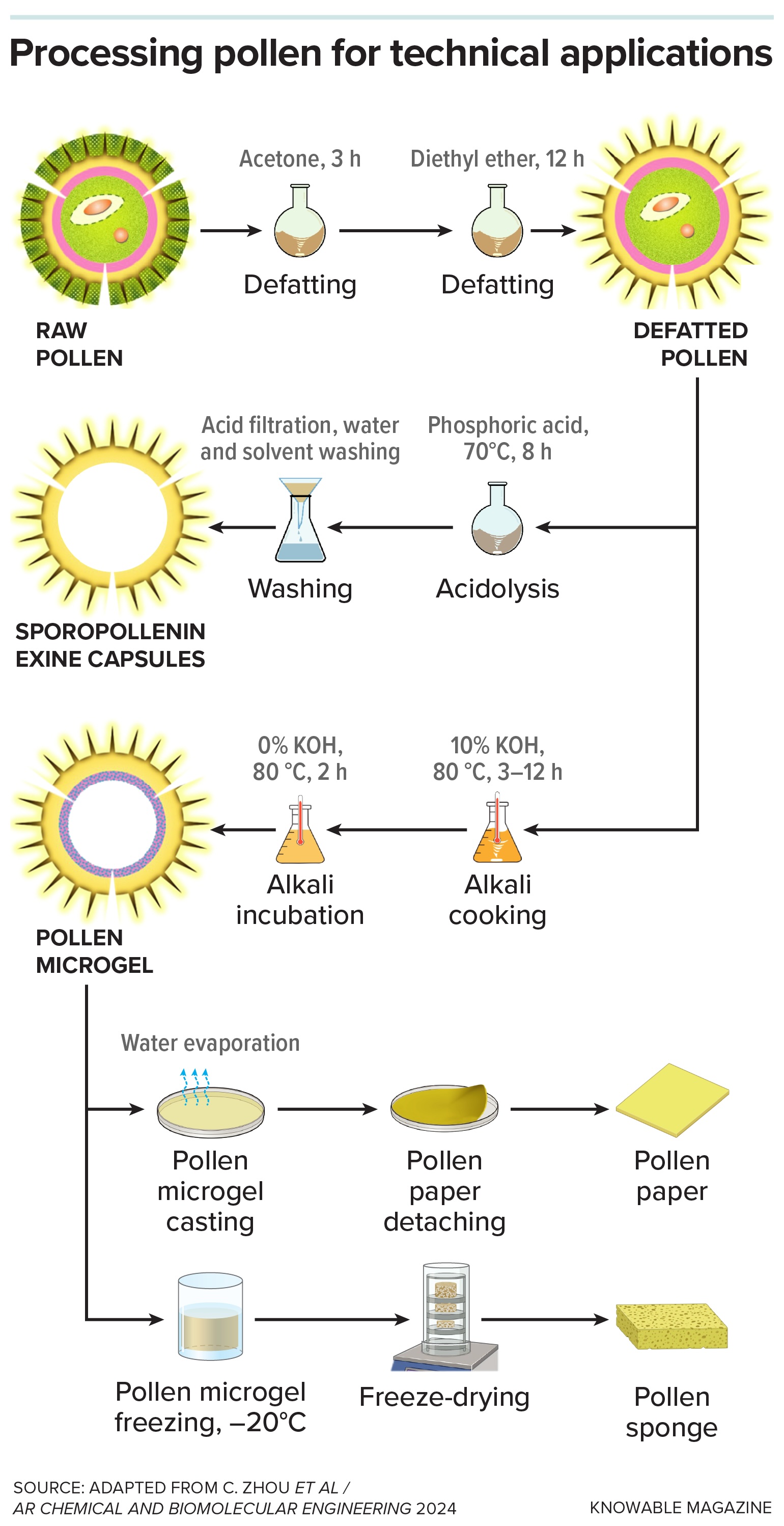

To start working with pollen, scientists can eliminate the sticky coating around the grains in a process called swing. Undressing these lipids and allergenic proteins is the first step to create empty capsules for the administration of drugs that CSABA is looking for. Beyond that, however, the apparently impenetrable shell of pollen – made up of biopolymer sporopollenin – had long perplexed researchers and has limited its use.

A breakthrough occurred in 2020, when Cho and its team pointed out that pollen incubation in an alkaline solution of potassium hydroxide at 80 degrees Celsius (176 degrees fahrenheit) could considerably change the surface chemistry of pollen grains, which would allow them to easily absorb and keep water.

The resulting pollen is as flexible as Play-Doh, explains Shahrudin Ibrahim, researcher in the Cho laboratory who helped develop the technique. Before treatment, pollen grains are more like balls: hard, inert and largely unrealed. Afterwards, the particles are so soft that they remain easily together, allowing more complex structures to form. This opens many applications, says Ibrahim, proudly holding a bottle of yellow melting snow in the laboratory.

When sunk on a flat and dried mold, the microgel assembles paper or film, depending on the final, strong but flexible thickness. It is also sensitive to external stimuli, including changes in pH and humidity. Exposure to the alkaline solution means that the constitutive polymers of pollen become more hydrophilic or that love water, therefore depending on the conditions, the frost will swell or shrink due to the absorption or expulsion of water, explains Ibrahim.

This winnings of properties, according to Singaporean researchers, make the film based on pollen a perspective for many future applications: intelligent actuators that allow devices to detect and react to changes in their environment, portable health trackers to monitor heart signals, and more. And because pollen is naturally protected by UVs, it is possible that it can substitute for certain substrates photonically active in perovskite solar cells and other optoelectronic devices.

The Cho laboratory has also shown that the paper made from pollen can be printed. It can be a lasting alternative to traditional paper for writing, printing and packaging, according to Cho, which has patented the microgel production process. The production of traditional paper destroys the trees and is with a high intensity of resources, requiring up to 13 liters of water for each page manufactured. Pollen is naturally released in bulk from plants producing seeds, and deriving from paper requires only a few simple steps. The ink can be removed with a simple alkaline solution washing – a process that allows you to reuse the paper.

In addition, the lyophilized pollen microgel forms porous sponges. These could be transformed into scaffolding for tissue engineering, or used to stem bleeding or to absorb oil spills.

The Cho team generally works with sunflower and camellia pollen which they buy at low cost like a mixture of bee pollen, mainly from China. But they say that their alkaline hydrolysis method would work well with a wide strip of plant species. The pollen is abundant, adds Cho – a single flip -flop in common sunflower, for example, produces 25,000 to 67,000 grains each summer. In addition, it is easy to collect bees in commercial hives.

Pollen -based products have a long way to go before reaching the market, adds Ibrahim; The key at the moment is to predict challenges and design lasting solutions. With other biomaterials, researchers work, such as chitosan and cellulose, a crustacean or a tree must be destroyed. Compared to this, pollen is considerably less with a high intensity of resources: “We do not destroy the plant,” he said. “We don’t even destroy flowers.”

This article originally appeared in Knowable MagazineA non -profit publication dedicated to making scientific knowledge accessible to all. Register for the newsletter of Knowable magazine.